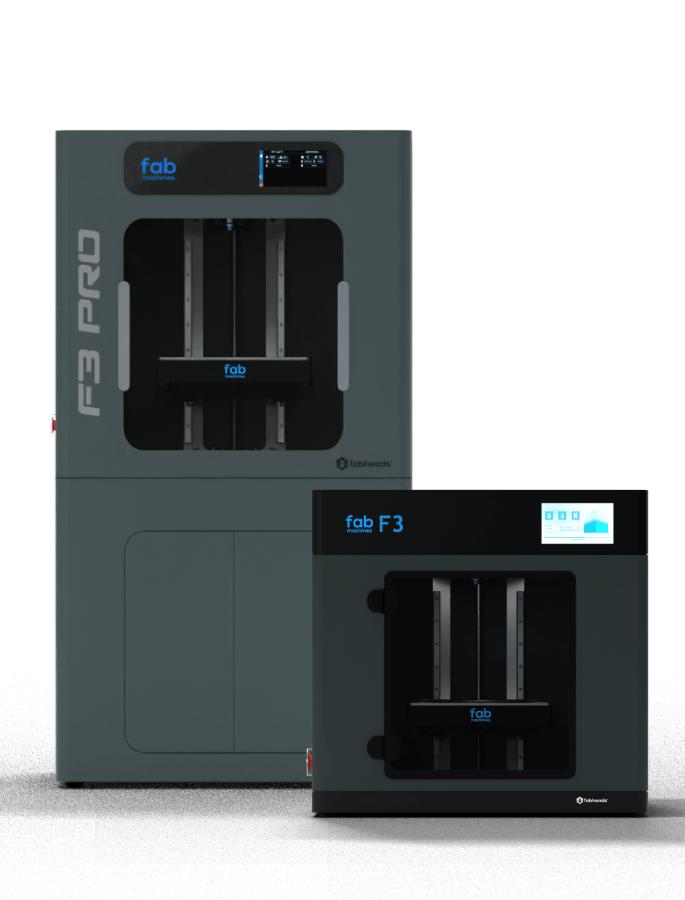

F-Series

Built for Carbon Fiber. Built for the Future.

India’s first and only Indigenous Continuous Fiber 3D Printer.

3D Print parts Faster and Stronger

3x

faster

Fiber deposition rate than others in the market today. Use upto 3k tex Fiber materials and deposit 3x more material at a time, thereby achieving significantly faster deposition rates and faster print times!

20x

stronger

than typical plastic 3D Printing.

Uses Continuous carbon fibers

reinforced plastics to print parts as strong as metals.

Best in class 3D Printing Technology for Continuous Fiber

Adaptive Tow Placement (ATP) Technology

Equipped with dual extruders, with one extruder powered by FabMachines’ proprietary Adaptive Tow Placement (ATP) 3D printing technology, which allows for Continuous fiber reinforced plastic materials to be 3D printed.

Best in Class Water Cooled Dual Extruder System

Fully sensor-driven water-cooled extruder system to print non-stop for days without end.

Choose from a Wide Range of Materials

30+

materials

Materials to suit a wide range of functionalities like strength, lightweight, corrosion resistance, etc.

Choose a mix of fiber and thermoplastic matrix of your choice

to meet your functional demands and we will custom-make the

material blend just for you..!

Fibers: Carbon, Glass and Kevlar

Matrix: PA12, PA6, PETG, ABS, ABS(ESD), etc.

Best in Class Software that is more than just a Slicing Tool

C6

platform

FabMachines G-Series machines are enhanced to another level with their

Software counterpart - The C6 Platform. India’s first cloud-based 3D printing software, completely designed and developed in-house.

More than just a slicer - Its unique features include:

- Cloud and browser based

- User & Project Management

- Version Management & Quality Control

More Smart Features

Smart Extrusion system!

Auto Bed Leveling, Clog prediction, Filament Run out Sensors and more such sensors coupled with Fabheads’ motherboard make it one of the smartest 3D printers.

Remote Control and Monitoring

With Cloud-based monitoring and remote accessibility, you can track the print progress, watch the print, and much more for a User-friendly experience.

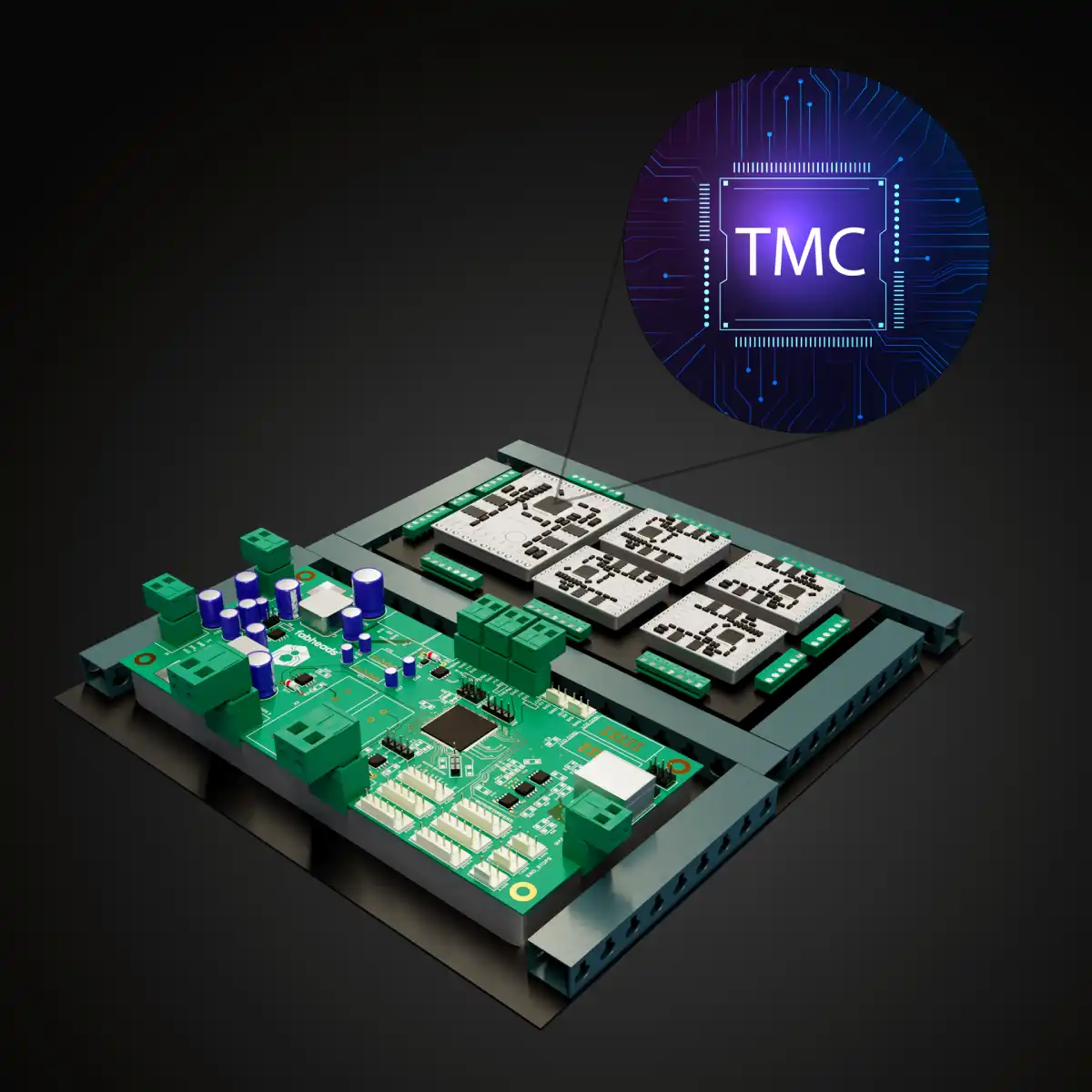

Precise Motion System

Motion system powered by TMC drivers and Hiwin rails that allows smooth movement of the print head which guarantees high resolution printed parts.

Fully Enclosed Build Volume

320x320x320 enclosed build volume maintains the temperature of the print.

Flexible build plate

Magnetic Flex plate ensures easier part removal with no hassle.

High Temperature Print Bed with Rapid Heating

Print Bed that heats up rapidly upto 150deg C eliminates warping and delamination

Amazing Returns on Investment

Focus on the essentials and boost your profit by saving your time and cost efficiently with FabMachines 3D Printers. Use our ROI calculator to see how FabMachines can save your overall cost..

Request Free Sample

Get in touch with the Next-gen, state of art technology 3D Printing Technology by requesting your sample here

| F3Pro | F3 | |

|---|---|---|

| Build Volume | 320 x 320 x 320 mm | 320 x 320 x 320 mm |

| Hot Ends | 2nos x Heli-CoolTM Extruders (Water Cooled Hot Ends) | 2nos x Heli-CoolTM Extruders (Water Cooled Hot Ends) |

| Filament Feed Chamber | Heats up to 80 ℃ | Heats up to 80 ℃ |

| Max. Bed Temperature | 150 ºC | 150 ºC |

| Maximum Extruder temperature | E1: 300 ℃ E2: 300 ℃ | E1: 300 ℃ E2: 300 ℃ |

| Z Resolution | 0.05mm | 0.05mm |

| Max. Print Speed | 100 mm/s (with no loss in print quality) | 100 mm/s (with no loss in print quality) |

| Motherboard | Fabheads’ FA-FF01-Mk1 | Fabheads’ FA-FF01-Mk1 |

Didn't find what you were looking for?

Want to consider a customized version of the above machine best fitting your requirements?

Or have other questions?