| F3Pro | F3 | G3Pro | G3 | |

|---|---|---|---|---|

General Specifcations |

||||

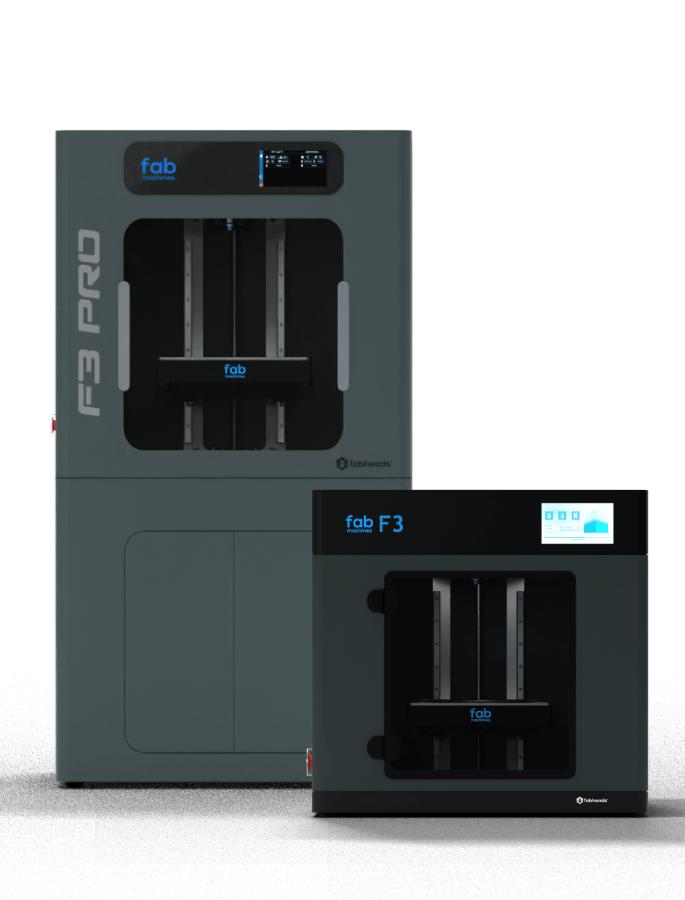

| 3D Printing Technology | Ext - 1: ATP (Adaptive Tow Placement) for Continuous Fiber Filament Ext- 2: FFF (Fused Filament Fabrication)" |

Ext - 1: ATP (Adaptive Tow Placement) for Continuous Fiber Filament Ext- 2: FFF (Fused Filament Fabrication)" |

Ext - 1: FFF (Fused Filament Fabrication) Ext- 2: FFF (Fused Filament Fabrication)" |

Ext - 1: FFF (Fused Filament Fabrication) Ext- 2: FFF (Fused Filament Fabrication)" |

| Build Volume | 320 x 320 x 320 mm | 320 x 320 x 320 mm | 320 x 320 x 320 mm | 320 x 320 x 320 mm |

| Hot Ends | 2nos x Heli-Cool™ Extruders (Water Cooled Hot Ends) | 2nos x Heli-Cool™ Extruders (Water Cooled Hot Ends) | 2nos x Heli-Cool™ Extruders (Water Cooled Hot Ends) | 2nos x Blizzard Air Cooled Hot Ends |

| Bed | Easily Removable Magnetic Flex Plate (PEI Coated) | Easily Removable Magnetic Flex Plate (Ceramic Coated) | Easily Removable Magnetic Flex Plate (PEI Coated) | Easily Removable Magnetic Flex Plate (Ceramic Coated) |

| Extrusion Architecture | FDEX-1A1F-Mk1 (One Bowden extruder config for ATP; One Bowden extruder config for FFF) | FDEX-1A1F-Mk1 (One Bowden extruder config for ATP; One Bowden extruder config for FFF) | FDEX-2F-Mk1 (Two Bowden extruder confg for FFF) | FDEX-2F-Mk1 (Two Bowden extruder config for FFF) |

| Filament Feed Chamber | Heats up to 80 ℃ | Heats up to 80 ℃ | Heats up to 80 ℃ | - |

| Material Feed Storage Humidity control | In line Dehydrator for dehumidification | N.A. | In line Dehydrator for dehumidification | N.A. |

Compatible Materials |

||||

| E1 Extruder | Continuous Fiber Reinforced Thermoplastics: Cont. CF-Nylon, Cont. CF-ABS, Cont. Aramid-Nylon, Cont. Aramid-ABS, etc. | Continuous Fiber Reinforced Thermoplastics: Cont. CF-Nylon, Cont. CF-ABS, Cont. Aramid-Nylon, Cont. Aramid-ABS, etc. | Granular/Chopped Fiber Reinforced Thermoplastics:

CF(G)-Nylon, CF(G)-ABS, CF(G)-PLA, GF(G)-Nylon, GF(G)-ABS, etc. Thermoplastics: PA, PC, ABS, PLA, PVA, PET-G, PP, ASA, BVOH, etc. |

Granular/Chopped Fiber Reinforced Thermoplastics:

CF(G)-Nylon, CF(G)-ABS, CF(G)-PLA, GF(G)-Nylon, GF(G)-ABS, etc. Thermoplastics: PA, PC, ABS, PLA, PVA, PET-G, PP, ASA, BVOH, etc. |

| E2 Extruder | Granular/Chopped Fiber Reinforced Thermoplastics:

CF(G)-Nylon, CF(G)-ABS, CF(G)-PLA, GF(G)-Nylon, GF(G)-ABS, etc. Thermoplastics: PA, PC, ABS, PLA, PVA, PET-G, PP, ASA, BVOH, etc. |

Granular/Chopped Fiber Reinforced Thermoplastics:

CF(G)-Nylon, CF(G)-ABS, CF(G)-PLA, GF(G)-Nylon, GF(G)-ABS, etc. Thermoplastics: PA, PC, ABS, PLA, PVA, PET-G, PP, ASA, BVOH, etc. |

Granular/Chopped Fiber Reinforced Thermoplastics:

CF(G)-Nylon, CF(G)-ABS, CF(G)-PLA, GF(G)-Nylon, GF(G)-ABS, etc. Thermoplastics: PA, ABS, PLA, PVA, PET-G, PP, ASA, BVOH, etc. |

Granular/Chopped Fiber Reinforced Thermoplastics:

CF(G)-Nylon, CF(G)-ABS, CF(G)-PLA, GF(G)-Nylon, GF(G)-ABS, etc. Thermoplastics: PA, PC, ABS, PLA, PVA, PET-G, PP, ASA, BVOH, etc. |

| Air Filter | HEPA Filter with suction fan | None (Available as add-on) | HEPA Filter with suction fan | None (Available as add-on) |

| Warranty | 2 years Warranty + first two years AMC (+ Fee based extension) | 1 year Warranty + first year AMC (+ Fee based extension) | 2 years Warranty + first two years AMC (+ Fee based extension) | 1 year Warranty + first year AMC (+ Fee based extension) |

PRINTING CONDITIONS |

||||

| Max. Bed Temperature | 150 ℃ | 150 ℃ | 150 ℃ | 120 ℃ |

| Maximum Extruder temperature | E1: 300 ℃ E2: 300 ℃ |

E1: 300 ℃ E2: 300 ℃ |

E1: 300 ℃ E2: 300 ℃ |

E1: 300 ℃ E2: 300 ℃ |

| Z Resolution | 0.05mm | 0.05mm | 0.05mm | 0.05mm |

| Positional Accuracy | X and Y axis: 25 μm Z axis: 10 μm |

X and Y axis: 25 μm Z axis: 10 μm |

X and Y axis: 25 μm Z axis: 10 μm |

X and Y axis: 25 μm Z axis: 10 μm |

| Max. Print Speed | 100 mm/s (with no loss in print quality) | 100 mm/s (with no loss in print quality) | 100 mm/s (with no loss in print quality) | 100 mm/s (with no loss in print quality) |

| Operating Conditions | Glycol Variant: -10 to 50 ℃ | Water Variant: 5 to 50 ℃ | Glycol Variant: -10 to 50 ℃ | 5 to 50 ℃ |

| Supported Raw Material format |

E1: 1.0-1.5k tex Towpreg (ATP filament format) - Upto 500g spool E2: 1.75 ± 0.05 mm (FFF Filament format) - Upto 1kg spool |

E1: 1.0-1.5k tex Towpreg (ATP filament format) - Upto 500g spool E2: 1.75 ± 0.05 mm (FFF Filament format) - Upto 1kg spool |

1.75 ± 0.05 mm (FFF Filament format) - Upto 1kg spool x 2nos. | 1.75 ± 0.05 mm (FFF Filament format) - Upto 1kg spool x 2nos. |

| Recommended Nozzle diameter |

E1: Fixed as per stock E2 for Thermoplastics: 0.2 - 1.0 mm E2 for Granular/Chopped fiber reinforced Thermoplastics: 0.4 - 1.0mm |

E1: Fixed as per stock E2 for Thermoplastics: 0.2 - 1.0 mm E2 for Granular/Chopped fiber reinforced Thermoplastics: 0.4 - 1.0mm |

For Thermoplastics: 0.2 - 1.0 mm For Granular/Chopped fiber reinforced Thermoplastics: 0.4 - 1.0mm |

For Thermoplastics: 0.2 - 1.0 mm For Granular/Chopped fiber reinforced Thermoplastics: 0.4 - 1.0mm |

Electronics |

||||

| Motherboard | Fabheads' FA-FF01-Mk1 | Fabheads' FA-FF01-Mk1 | Fabheads' FA-GG01-Mk1 | Fabheads' FA-GG01-Mk1 |

| Processor |

Micro Controller: Atmega 2560 Server: Broadcom BCM2711, Quad core Cortex-A72 (ARM v8) 64-bit SoC @ 1.5GHz |

Micro Controller: Atmega 2560 Server: Broadcom BCM2711, Quad core Cortex-A72 (ARM v8) 64-bit SoC @ 1.5GHz |

Micro Controller: Atmega 2560 Server: Broadcom BCM2711, Quad core Cortex-A72 (ARM v8) 64-bit SoC @ 1.5GHz |

Micro Controller: Atmega 2560 Server: Broadcom BCM2711, Quad core Cortex-A72 (ARM v8) 64-bit SoC @ 1.5GHz |

| Motor Drivers | TMC5160 with Sensorless Homing and fault detection | TMC5160 with Sensorless Homing and fault detection | TMC5160 with Sensorless Homing and fault detection | TMC5160 with Sensorless Homing and fault detection |

| Firmware | Marlin v2.x | Marlin v2.x | Marlin v2.x | Marlin v2.x |

Sensors |

||||

| Clog Detection | ✓ | ✕ | ✓ | ✕ |

| Filament Runout Detection | ✓ | ✓ | ✓ | ✓ |

| Bed Leveling Sensor | ✓ | ✓ | ✓ | ✓ |

| Sensorless End Stop | ✓ | ✓ | ✓ | ✓ |

User Interface & Connectivity |

||||

| Direct HMI Interface | 7” Full color Capacitive LCD Touch Screen | 7” Full color Capacitive LCD Touch Screen | 7” Full color Capacitive LCD Touch Screen | 7” Full color Capacitive LCD Touch Screen |

| Remote Interface | Mobile / Desktop / Laptop (Browser based) | Mobile / Desktop / Laptop (Browser based) | Mobile / Desktop / Laptop (Browser based) | (Available as Add-on) |

| Offline Print Input Mode | USB Pendrive / USB interface with computer | USB Pendrive / USB interface with computer | USB Pendrive / USB interface with computer | USB Pendrive / USB interface with computer |

| Online Print Input Mode (Remote Control / Monitor) | WiFi (through Server) Mobile / Desktop / Laptop (Browser based) | WiFi (through Server) Mobile / Desktop / Laptop (Browser based) | WiFi (through Server) Mobile / Desktop / Laptop (Browser based) | (Available as Add-on) |

Chassis and Gantry |

||||

| Chassis | Precision machined Die-cast Aluminum Chassis | Precision machined Die-cast Aluminum Chassis | Precision machined Die-cast Aluminum Chassis | Precision machined Die-cast Aluminum Chassis |

| Gantry |

X & Y Axis: Hiwin Rails - Belt Driven Actuation Z Axis: Hiwin Rails - Lead Screw Actuation |

X & Y Axis: Hiwin Rails - Belt Driven Actuation Z Axis: Hiwin Rails - Lead Screw Actuation |

X & Y Axis: Hiwin Rails - Belt Driven Actuation Z Axis: Hiwin Rails - Lead Screw Actuation |

X & Y Axis: Hiwin Rails - Belt Driven Actuation Z Axis: Hiwin Rails - Lead Screw Actuation |

| Shell | SS Sheet Metal Body with Polycarbonate panels and doors | Aluminum Sheet Metal Body with Polycarbonate panels and doors | SS Sheet Metal Body with Polycarbonate panels and doors | Aluminum Sheet Metal Body with Polycarbonate panels and doors |

| Storage | 300 ltr of storage (Optionally Removable) | 300 ltr of storage (Optionally Removable) | ||

Machine Details |

||||

| Electrical Input | AC 200-240V, 50Hz Indian Standard | AC 200-240V, 50Hz Indian Standard | AC 200-240V, 50Hz Indian Standard | AC 200-240V, 50Hz Indian Standard |

| Maximum power consumption | 1100 W | 1100 W | 1100 W | 800W |

| Overall dimensions | 810mm (W) x 670mm (D) x 800mm (H) | 810mm (W) x 670mm (D) x 800mm (H) | 810mm (W) x 670mm (D) x 800mm (H) | 810mm (W) x 670mm (D) x 800mm (H) |

| Overall Weight | 110 kg (without raw materials) | 80kg (without raw materials) | 110kg (without raw materials) | 80kg (without raw materials) |